MDOPE-S Film(Extremely High Barrier)Metallized is an elastic film that provides high energy absorption in drop testing which allows excellent bag integrity for pouches with heavy contents or liquids. The metallization adds visual finishing effects for an opaque and shiny look. This film can serve as a middle layer in a triplex structure and replace non-recyclable metallized films.

TOPESOL’s MDOPE-S Film(Extremely High Barrier) features a soft and elastic structure that facilitates enhanced energy retention on drop and ensures excellent sealing performance and overall pouch integrity. that enables robust laminates that can hold liquids and heavy content goods.

*Unless otherwise stated, all performance is tested under standard laboratory condition: 23 ± 2 º C; 50 ± 5% RH.In relevant cases, testing is base on international testing standards.

Application

Excellent equipment & better effect of roll film

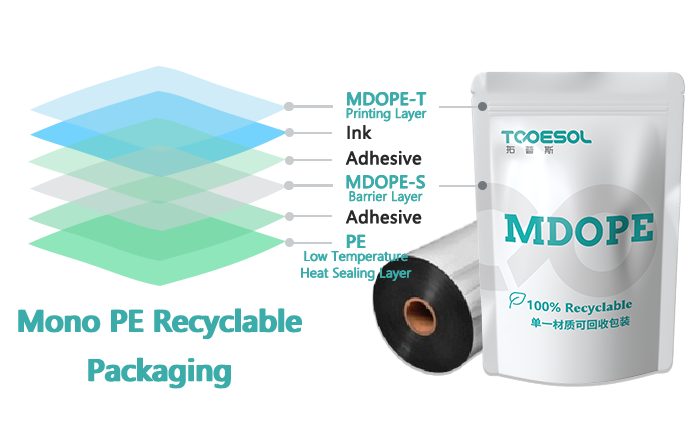

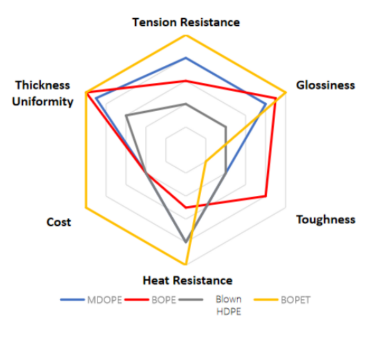

TOPESOL’s MDOPE material has high tensile strength, excellent flatness and printability.It can maintain stable processing stability in subsequent coating, printing, laminating and pouch making process.

TOPESOL’s MDOPE material has good printing performance as PET, which can completely replace PET as the printing material of the surface layer, and is the best material for mono material recyclable packaging.

TOPESOL’s MDOPE material can be tailored to meet specific requirements such as high transparency and gloss, low or high haze etc.

TOPESOL’s MDOPE material provide good barrier performance to improve the poor barrier of ordinary recyclable packaging, and expand the application range of recyclable packaging.

Enable the production with thinner film material while retaining the same barrier properties of thicker films, it means that require less materials, less packaging and less transportation costs, thus reducing CO2 footprint, while retaining and improving film properties.

Film enters the MDO stretching unit and is evenly preheated to a required temperature.

Film is nipped between a series of rollers revolving at various speeds for stretching.

Film is stabilized, and its altered properties are locked and retained.

Film is cooled to near room temperature.

MDOPE-T Film(Common) is a rigid film that provides excellent package stability with a straight and easy tear in machine direction.

A high modulus and use of high-quality resins ensure MDOPE-E Film (High Barrier) grade’s machinability on any printing and converting line

High stiffness, heat resistance, easy tearing at MD and high transparency. It is suitable for the printing layer of mono PE packaging replacing PET

Common PE films perform high strength, high stiffness, heat resistance, easy tearing at MD and high transparency. It is suitable for the printing layer of mono PE packaging replacing PET.

High barrier MDOPE has coating barrier layer or extrusion barrier layer, achieving excellent oxygen barrier and aroma preservation.

Thickness:20-40um

Width:500-2200mm

Extremely high barrier MDOPE film performs excellent water vapor barrier property. Special formula films enhance both oxygen barrier and aroma preservation. It is available for product packaging with higher requirement on shelf life.

Thickness:21-40um

Width:500-2200mm

Please provide the following details to help our sales represent to understand your needs, and get in touch with you as soon as possible